Our company's technical people customize products in terms of size, parameters and other aspects according to the actual requirements of customers. Produced exactly according to customer requirements.Each production process is set in strict accordance with production requirements, and product quality is strictly controlled.

Heat treatment is a key process that affects product quality. The heat treatment temperature should be set according to the raw materials used. For example, for the heat treatment of medium carbon steel with higher carbon content, it is not advisable to use too high normalizing temperature and long holding time, otherwise it will cause serious damage. Carbon breaks out on the gear surface and reduces the hardness. Therefore, it is necessary to normalize and heat slowly. After 4 hours, the temperature rises to 810-860°C. After 6 hours of insulation, take it out of the furnace and cool it at room temperature in ventilated air.Ability to customize various types of large ring gears according to drawings and dimensions provided by customers.

Depai cast steel large rotary kiln gear has unique advantages. The large ring gear adopts mature heat treatment technology during casting, which optimizes the structure of the ring gear, improves the hardness, and greatly enhances the wear resistance and impact resistance of the product.

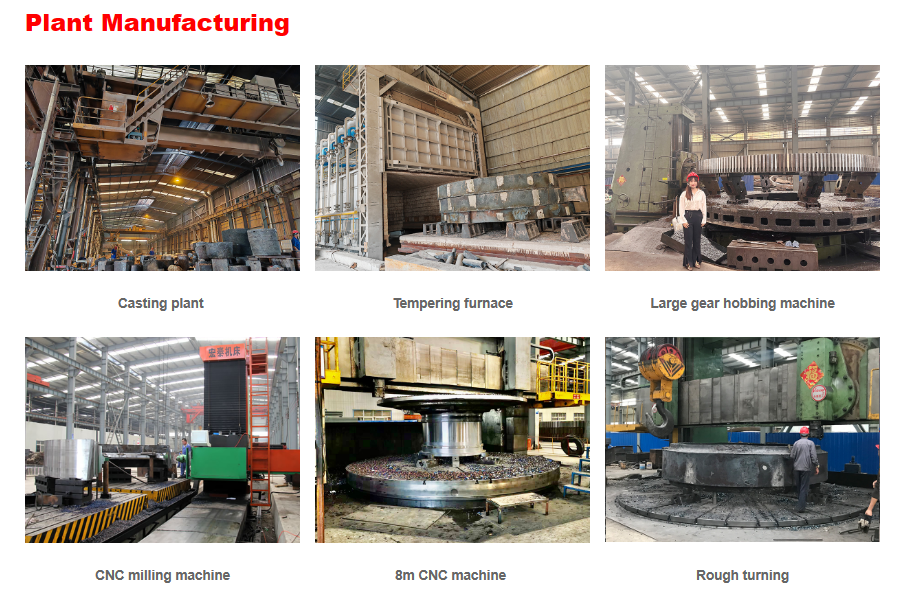

We have served customers in the mining industry for nearly 20 years, providing various large-scale casting products for rotary kilns and ball mills.The factory has 10T and 15T energy-saving variable frequency induction electric furnaces, and uses a spectrometer for automatic material analysis, mechanical tensile testing, and hardness testing. The casting capacity reaches 40 tons/piece, and the annual production of various ordinary carbon steels and low alloy steels is 12,000 tons. It has a natural gas normal-fired kiln of 8m×6.5m×2.4m. It has large-scale metal processing equipment such as 3.5m, 4m, 5m, and 8m vertical lathes, 2m, 3m, 5m, and 8m gear hobbing machines, 160 CNC boring and milling machines, CNC milling machines, and drilling machines. Provide customers with one-stop service from product design to processing.

For any more customized information, contact us : info@dpmachinery.com

Name: Ms Linda Ren

Tel:0086 15366795302

Whatsapp:008615366795302

Email:info@dpmachinery.com

Add:17th floor No.10 building, Tianfu Square,Tongshan district Xuzhou, Jiangsu Province, China--221000